THE MACHINEThe LST and LT machines are fully automated machines, available in several sizes designed to meet the latest cGMP Standards. The smallest unit can process 6,000 x 20 mm. standard stoppers; and the largest unit, roughly 100,000 x 20 mm. standard stoppers. The complete cycle time for Model LST, which includes sterilization, is approximately 3.5 hours offering guaranteed residual moisture content down to 0.01%. The duration of the complete cycle without sterilization is approximately 2-2.5 hours.

FlexibilityAn outstanding feature of this machine is that it can be used for rubber stoppers, aluminum line-seals (combi-caps), syringe plungers, and screw caps for vials with the same proven results.

Individual basket concept. Individual baskets aid in better physical separation of the stoppers. To load all the stoppers into one main chamber encourages clumping and interlocking which diminishes surface exposure. By separating the stoppers, there is little or no mass weight to cause interlocking, offering a maximum surface exposure during each phase of an entire cycle.

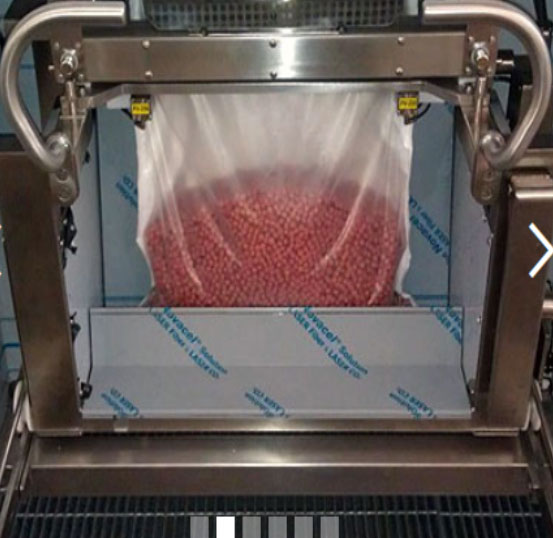

Product unloading:

A critical factor in uniformity and effectiveness of the stopper processing is the capability of increasing surface exposure during the cycle. By separating the stoppers we increase the surface exposure to process fluids:

Other reasons for the worldwide success of our machine:

All of the stopper processor models can easily interface with isolators proposed and supplied by any of the world’s current manufacturers, in which ICOS has extensive experience.

All standard ICOS equipment is furnished with CFR21 part 11 compliant control systems. Ifix platform is available as well as Siemens or Allen Bradley PLC.

The use of only one piece of equipment reduces material handling significantly. It is easier to validate, occupies less floor space, requires less maintenance, and at the same time improves the quality of your product(s).